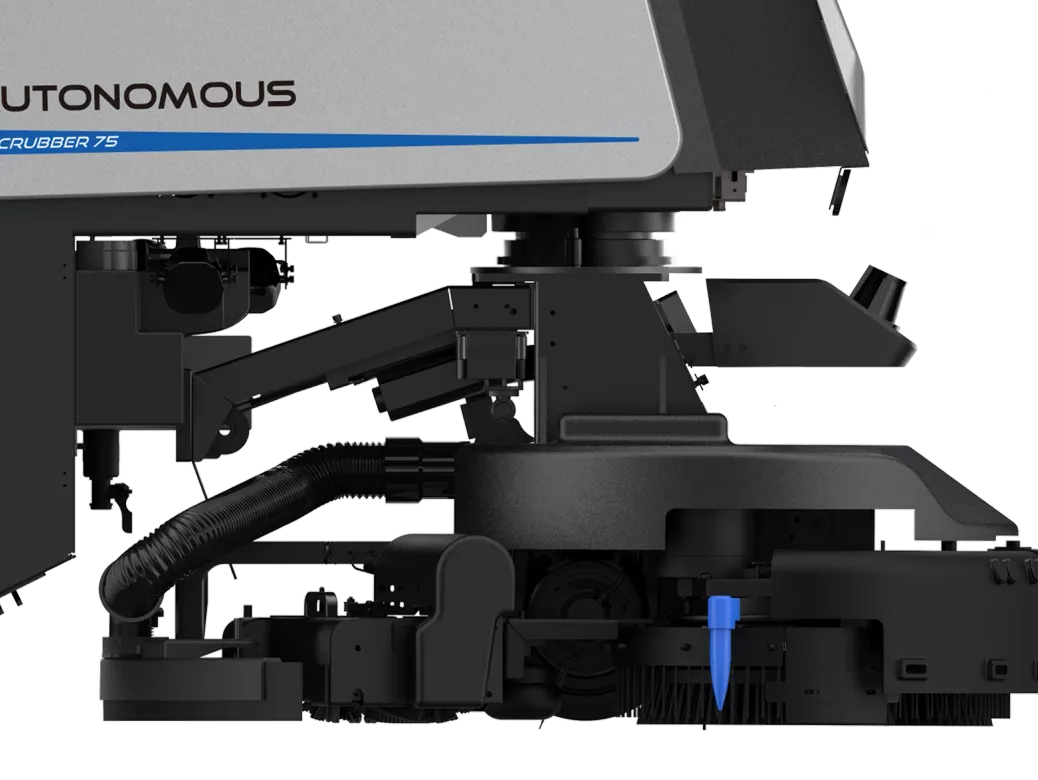

Cleaning robot

Autonomous cleaning robots perform various cleaning tasks such as scrubbing, sweeping, dusting, and degreasing simultaneously. It is highly efficient and can clean up to 2000 sqm per hour, making it perfect for cleaning large industrial spaces.